XUSUSIYATLAR

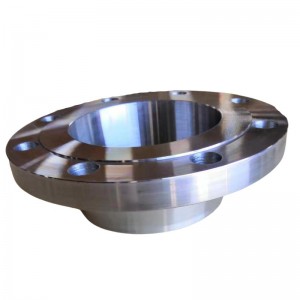

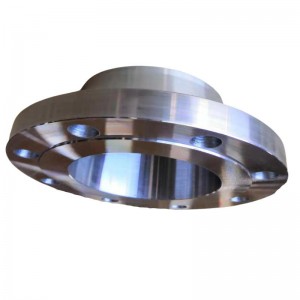

| Mahsulot nomi | payvandlash bo'yin gardishi |

| Hajmi | 1/2"-24" |

| Bosim | 150#-2500#,PN0.6-PN400,5K-40K |

| Standart | ANSI B16.5, EN1092-1, JIS B2220 va boshqalar. |

| Stub uchi | MSS SP 43, ASME B16.9 |

| Materiallar | Zanglamaydigan po'lat:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo va boshqalar. |

| Uglerodli po'lat:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 va boshqalar. | |

| Dupleks zanglamaydigan po'lat:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 va boshqalar. | |

| Quvur po'lati:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 va boshqalar. | |

| Nikel qotishmasi:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 va boshqalar. | |

| Cr-Mo qotishmasi:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo va boshqalar. | |

| Ilova | Neft-kimyo sanoati; aviatsiya va aerokosmik sanoati; farmatsevtika sanoati; gaz chiqindilari; elektr stantsiyasi; kema qurish; suvni tozalash va boshqalar. |

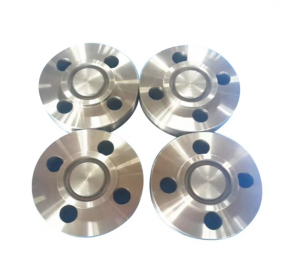

| Afzalliklari | tayyor zaxira, tezroq yetkazib berish vaqti; barcha o'lchamlarda mavjud, moslashtirilgan; yuqori sifatli |

O'LCHAM STANDARTLARI

MAHSULOTLAR TAFSILOTLARI KO'RSATISH

1. Yuz

Yuzni ko'tarish (RF), to'liq yuzni (FF), halqali bo'g'inni (RTJ), yivni, tilni yoki moslashtirilgan bo'lishi mumkin.

2. ANSI B16.25 ga muvofiq qiya uchi

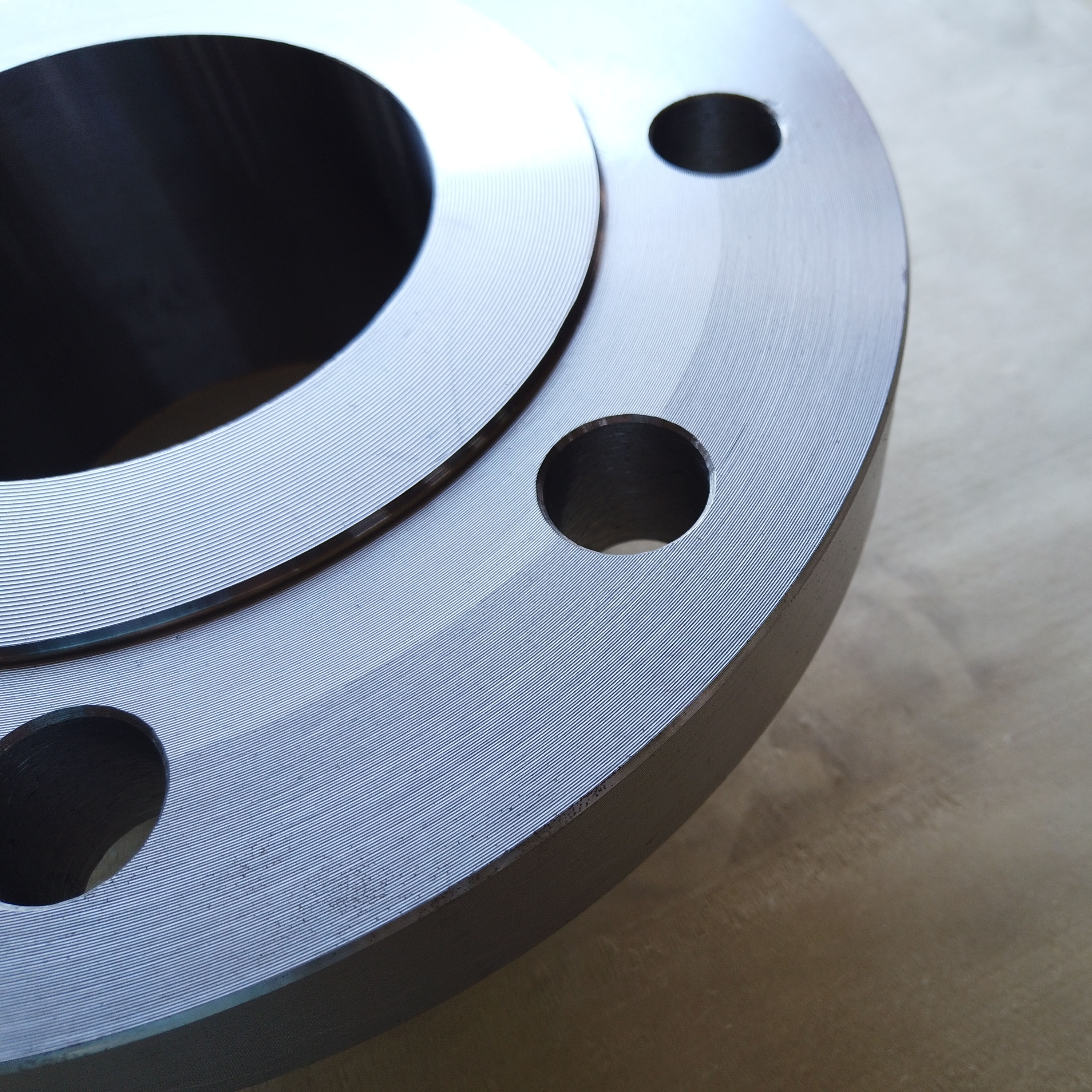

3.CNC nozik ishlangan.

Yuz qoplamasi: Flanes yuzasidagi qoplama Arifmetik o'rtacha qo'pollik balandligi (AARH) sifatida o'lchanadi. Yakunlash qo'llaniladigan standart bo'yicha aniqlanadi. Masalan, ANSI B16.5 125AARH-500AARH (3.2Ra dan 12.5Ra gacha) oralig'ida yuz qoplamalarini belgilaydi. Talabga binoan boshqa qoplamalar ham mavjud, masalan, maksimal 1.6 Ra, 1.6/3.2 Ra, 3.2/6.3Ra yoki 6.3/12.5Ra. 3.2/6.3Ra diapazoni eng keng tarqalgan.

BELGILASH VA QADOQLASH

• Har bir qatlam sirtni himoya qilish uchun plastik plyonkadan foydalanadi

• Barcha zanglamaydigan po'latlar uchun kontrplak korpusi bilan qadoqlangan. Katta o'lchamdagi uglerod flanjlari uchun kontrplak pallet bilan qadoqlangan. Yoki moslashtirilgan qadoqlash mumkin.

• Yuk tashish belgisi so'rov bo'yicha amalga oshirilishi mumkin

• Mahsulotlardagi belgilar o'ymakorlik yoki bosma nashrlarda chop etilishi mumkin. OEM qabul qilinadi.

TEKSHIRUV

• UT testi

• PT testi

• MT testi

• O'lcham sinovi

Yetkazib berishdan oldin, bizning QC guruhimiz NDT sinovi va o'lchov tekshiruvini tashkil qiladi. Shuningdek, TPI (uchinchi tomon tekshiruvi) ni qabul qiladi.

ISHLAB CHIQARISH JARAYONI

| 1. Asl xom ashyoni tanlang | 2. Xom ashyoni kesib oling | 3. Oldindan isitish |

| 4. Soxtalashtirish | 5. Issiqlik bilan ishlov berish | 6. Qo'pol ishlov berish |

| 7. Burg'ulash | 8. Nozik ishlov berish | 9. Belgilash |

| 10. Tekshirish | 11. Qadoqlash | 12. Yetkazib berish |

HAMKORLIK ISHI

Turkiyadagi loyiha bo'yicha flanjlar tabiiy gaz quvurlarida ishlatiladi. Bu flanjlarning barchasi TUV tomonidan tasdiqlangan.

FLANJ MA'LUMOTLARI VARAQASI

1Flanes o'lchamlari va bardoshliklari ASME B16.5 ga muvofiq bo'lishi kerak.

2. Flanjlar zarb qilish yo'li bilan ishlab chiqariladi.

3. Materiallar ASTM A105, ASTM A694 F65 va ASTM A694 F70 standartlariga muvofiq bo'lishi kerak.

4. ASTM A694 F65 va ASTM A694 F70 flanjlari o'chirilishi va chiniqtirilishi kerak.

5. Materiallarni sinovdan o'tkazish sertifikatlari va issiqlik bilan ishlov berish hisobotlari TPI tekshiruvlari uchun taqdim etilishi kerak.

6. WN flanjlari ASME B16.25 ga muvofiq qiyshiq uchlarga ega bo'lishi kerak.

7. Materiallarning kimyoviy va mexanik sinov qiymatlari (zarba, oqim, cho'zilish va boshqalar) tegishli standartlarga muvofiq bo'lishi kerak.

8. Zanglamaslik uchun barcha sirtlar ishlov berilishi va shaffof moy bilan laklanishi kerak.

9. Belgilash quyidagi ma'lumotlarni o'z ichiga olishi kerak,

• Diametr (taxminan 6”)

• Bosim klassi (taxminiy 150 LB)

• Material darajasi (ASTM A 105 standartiga muvofiq)

• Devor qalinligi (taxminiy 4,78 mm)

• Issiqlik raqami (amal qilish muddati 138413)

• Ishlab chiqarish standarti (ASME B16.5)

10. Materiallar har qanday sirt nuqsonlari va yoriqlaridan xoli bo'lishi kerak. Payvandlash ta'mirlash qat'iyan man etiladi.

11. Barcha gardishlar ko'tarilgan yuza (RF) bo'lishi va muhrlash yuzasi bo'lishi kerak. Muhrlash yuzasi ASME B46.1 ga muvofiq Ra 3,2 – 6,3 µm (125 – 250 mikron) bo'lishi kerak.

12. Materiallar ishlov berishga zarar yetkazmaslik va sirtlarni yopish uchun qadoqlangan bo'lishi kerak.

13. Barcha o'lchamlar musbat (+) tolerantliklarda bo'lishi kerak. Minus tolerantliklarga qat'iyan yo'l qo'yilmaydi.

14. Flanes qiyaligi ASME B16.25 ga muvofiq amalga oshirilishi kerak.

15. Ishlab chiqarish jarayoni istalgan vaqtda TPI tomonidan tekshiriladi.

16. TPI kimyoviy/mexanik sinov namunasi uchun har qanday materialdan namunalar olishi mumkin.

17. Kiruvchi tekshirish hisoboti TPI tomonidan ko'rib chiqiladi.

| Mahsulot | Hajmi (dyuym) | Bosim sinfi | CS | Materiallar | Og'irligi (mm) | Joylashuv | Miqdori |

| SORF | 12 | 150 funt | 20 | A105 | - | BANK FLANGLARI | 48 |

| SORF | 8 | 150 funt | 20 | A105 | - | BANK FLANGLARI | 32 |

| SORF | 3 | 150 funt | 20 | A105 | - | BANK FLANGLARI | 32 |

| Flanj, payvandlangan bo'yin | 24 | 150 funt | 20 | A105 | 14 | BANK FLANGLARI | 2 |

| Flanj, payvandlangan bo'yin | 24 | 150 funt | 20 | A105 | 5.54 | BANK FLANGLARI | 4 |

| SORF | 20 | 150 funt | 20 | A105 | - | BANK FLANGLARI | 6 |

| Flanj, payvandlangan bo'yin | 24 | 150 funt | 20 | A105 | 5.54 | BANK FLANGLARI | 8 |

| Flanj, payvandlangan bo'yin | 24 | 150 funt | 20 | A105 | 14 | BANK FLANGLARI | 8 |

| Flanj, payvandlangan bo'yin | 24 | 150 funt | 20 | A105 | 16 | BANK FLANGLARI | 8 |

| SORF | 3 | 150 funt | 20 | A105 | - | BANK FLANGLARI | 24 |

| SORF | 20 | 150 funt | 20 | A105 | - | BANK FLANGLARI | 6 |

| Flanj, payvandlangan bo'yin | 24 | 150 funt | 20 | A105 | 5.54 | BANK FLANGLARI | 8 |

| Flanj, payvandlangan bo'yin | 24 | 150 funt | 20 | A105 | 14 | BANK FLANGLARI | 16 |

| Mahsulot | Hajmi (dyuym) | Bosim sinfi | CS | Materiallar | Og'irligi (mm) | Joylashuv | Miqdori |

| Flanj, payvandlangan bo'yin | 24 | 400 funt | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flanj, payvandlangan bo'yin | 20 | 400 funt | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flanj, payvandlangan bo'yin | 24 | 400 funt | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flanj, payvandlangan bo'yin | 20 | 400 funt | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flanj, payvandlangan bo'yin | 12 | 400 funt | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flanj, payvandlangan bo'yin | 4 | 400 funt | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flanj, payvandlangan bo'yin | 24 | 400 funt | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flanj, payvandlangan bo'yin | 4 | 400 funt | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flanj, payvandlangan bo'yin | 24 | 400 funt | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flanj, payvandlangan bo'yin | 20 | 400 funt | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flanj, payvandlangan bo'yin | 24 | 400 funt | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flanj, payvandlangan bo'yin | 20 | 400 funt | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flanj, payvandlangan bo'yin | 12 | 400 funt | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flanj, payvandlangan bo'yin | 24 | 400 funt | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flanj, payvandlangan bo'yin | 4 | 400 funt | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flanj, payvandlangan bo'yin | 10 | 300 funt | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flanj, payvandlangan bo'yin | 6 | 300 funt | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flanj, payvandlangan bo'yin | 4 | 300 funt | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flanj, payvandlangan bo'yin | 18 | 300 funt | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flanj, payvandlangan bo'yin | 8 | 300 funt | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flanj, payvandlangan bo'yin | 8 | 300 funt | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

TSS

1. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanesi nima?

AMSE B16.5 A105 Soxta uglerodli po'latdan yasalgan payvandlash gardishi quvur tizimlarida ishlatiladigan maxsus gardish turini anglatadi. U A105 uglerodli po'latdan yasalgan va ishonchli, oqmaydigan ulanishni ta'minlash uchun payvandlangan bo'yinli dizaynga ega.

2. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanesining asosiy xususiyatlari nimada?

AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlarining asosiy xususiyatlari yuqori mustahkamlik, chidamlilik va korroziyaga chidamlilikni o'z ichiga oladi. U sanoat muhitida yuqori bosim va yuqori haroratli qo'llanilishlarga bardosh berish uchun mo'ljallangan.

3. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanesini qayerda ishlatish mumkin?

AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari neft va gaz, neft-kimyo, energiya ishlab chiqarish va suvni tozalash kabi turli sohalarda qo'llaniladi. Ular ko'pincha quvurlar yoki klapanlarni xavfsiz ulash uchun quvur tizimlarida qo'llaniladi.

4. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanesini qanday o'rnatish mumkin?

AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash gardishini o'rnatish uchun avval gardish quvur yoki klapan uchiga payvandlanadi. Keyin payvandlash bo'yni boshqa quvur yoki uskunadagi mos keladigan gardish bilan murvat va shaybalar yordamida mahkam va oqmaydigan ulanish hosil qilish uchun ulanadi.

5. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlaridan foydalanishning afzalliklari nimada?

AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlaridan foydalanishning ba'zi afzalliklari orasida uning yuqori mustahkamlikdagi konstruktsiyasi mavjud bo'lib, bu ishonchli va uzoq muddatli ulanishni ta'minlaydi. Ular, shuningdek, suyuqliklar va gazlarning uzluksiz oqishini ta'minlaydi, turbulentlikni minimallashtiradi va eroziya yoki korroziyani kamaytiradi.

6. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari uchun qanday o'lcham va bosimni baholash variantlari mavjud?

AMSE B16.5 A105 Soxta uglerod po'latdan yasalgan payvandlash flanjlari turli o'lchamlarda, diametri 1/2 dyuymdan 36 dyuymgacha mavjud. Ular, shuningdek, 150, 300, 600, 900, 1500 va 2500 kabi turli bosim darajalarida ham mavjud.

7. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari bilan oqishsiz ulanishni qanday ta'minlash mumkin?

AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari bilan oqishsiz ulanishni ta'minlash uchun, murvatlarni mahkamlashdan oldin flanjlar to'g'ri hizalanishi kerak. Xavfsiz va ishonchli ulanishga erishish uchun tavsiya etilgan texnik xususiyatlarga muvofiq yetarli murvat momenti qo'llanilishi kerak.

8. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari yuqori bosimli va yuqori haroratli dasturlarda ishlatilishi mumkinmi?

Ha, AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari yuqori bosim va yuqori harorat sharoitlariga bardosh berish uchun mo'ljallangan. Biroq, ulanishning yaxlitligini saqlab qolish uchun flanj va unga tegishli komponentlarning ma'lum ish sharoitlariga mos kelishini ta'minlash muhimdir.

9. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari qo'shimcha germetik materialni talab qiladimi?

Ha, AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari flanj yuzalari o'rtasida muhrni ta'minlash uchun qistirmalardan foydalanishni talab qiladi. Qistirma materiali tashilayotgan suyuqlik yoki gaz turiga va ish sharoitlariga bog'liq. To'g'ri qistirma materialini tanlash oqishning oldini olish uchun juda muhimdir.

10. AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanjlari bozorda osongina mavjudmi?

Ha, AMSE B16.5 A105 zarb qilingan uglerod po'latdan yasalgan payvandlash flanesi bozorda keng tarqalgan. Ular quvurlarni yig'ishga ixtisoslashgan turli xil vakolatli dilerlar va ishlab chiqaruvchilardan sotib olish mumkin bo'lgan keng tarqalgan flanes turidir.

Quvur armaturalari quvur tizimidagi muhim komponentlar bo'lib, suyuqliklarni ulash, yo'naltirish, yo'naltirish, o'lchamlarni o'zgartirish, muhrlash yoki boshqarish uchun ishlatiladi. Ular qurilish, sanoat, energetika va kommunal xizmatlar kabi sohalarda keng qo'llaniladi.

Asosiy funktsiyalar:U quvurlarni ulash, oqim yo'nalishini o'zgartirish, oqimlarni ajratish va birlashtirish, quvur diametrlarini sozlash, quvurlarni muhrlash, boshqarish va tartibga solish kabi funktsiyalarni bajarishi mumkin.

Qo'llanilish doirasi:

- Binolarni suv bilan ta'minlash va drenajlash:Suv quvurlari tarmoqlari uchun PVX tirsaklar va PPR trislari ishlatiladi.

- Sanoat quvurlari:Kimyoviy muhitni tashish uchun zanglamaydigan po'latdan yasalgan flanjlar va qotishma po'latdan yasalgan tirsaklar ishlatiladi.

- Energiya tashish:Yuqori bosimli po'lat quvur armaturalari neft va gaz quvurlarida qo'llaniladi.

- HVAC (Isitish, shamollatish va konditsionerlash):Mis quvur armaturalari sovutgich quvurlarini ulash uchun, egiluvchan bo'g'inlar esa tebranishni kamaytirish uchun ishlatiladi.

- Qishloq xo'jaligi sug'orish:Tezkor ulagichlar purkagichli sug'orish tizimlarini yig'ish va demontaj qilishni osonlashtiradi.

-

teshik gardish WN 4″ 900# RF A105 dual gr...

-

Ansi B16.5 A105 Qora Karbonli Chelik Slip On Flanş

-

Soket payvandlash gardishi A105 uglerodli po'lat SW RTJ 3/4...

-

Jek bilan zarb qilingan asme b16.36 wn teshikli gardish ...

-

ASME B16.5 BL RF ASTM A182 F316L zanglamaydigan po'latdan yasalgan ...

-

Maxsus yuqori sifatli 304 zanglamaydigan po'latdan yasalgan flanesli ...