MAHSULOT PARAMETRLARI

| Mahsulot nomi | Quvur tirsagi |

| Hajmi | 1/2"-36" choksiz tirsak (SMLS tirsagi), 26"-110" chok bilan payvandlangan. Eng katta tashqi diametri 4000 mm bo'lishi mumkin |

| Standart | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75 va boshqalar. |

| Devor qalinligi | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS va boshqalar. |

| Daraja | 30° 45° 60° 90° 180° va boshqalar |

| Radius | LR/uzun radius/R=1.5D, SR/Qisqa radius/R=1D |

| Oxiri | Eğimli uchi/BE/dumba |

| Sirt | tabiiy rang, laklangan, qora bo'yoq, zangga qarshi moy va boshqalar. |

| Materiallar | Uglerodli po'lat:A234WPB, A420 WPL6 St37, St45, E24, A42CP, 16Mn, Q345, P245GH, P235GH, P265GH, P280GH, P295GH, P355GH va boshqalar. |

| Quvur po'lati:ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 va boshqalar. | |

| Cr-Mo qotishma po'lati:A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3, 12crmov va boshqalar. | |

| Ilova | Neft-kimyo sanoati; aviatsiya va aerokosmik sanoati; farmatsevtika sanoati, gaz chiqindilari; elektr stantsiyasi; kema qurish; suvni tozalash va boshqalar. |

| Afzalliklari | tayyor zaxira, tezroq yetkazib berish vaqti; barcha o'lchamlarda mavjud, moslashtirilgan; yuqori sifatli |

QUVUR FITTINGLARI

Tugmachali payvandlangan quvur armaturalari po'lat quvur tirsagi, po'lat quvur troyni, po'lat quvur reduktori, po'lat quvur qopqog'ini o'z ichiga oladi. Bularning barchasini biz birgalikda yetkazib bera olamiz, bizda 20 yildan ortiq ishlab chiqarish tajribasi mavjud.

Agar siz boshqa armaturalarga ham qiziqsangiz, tafsilotlarni tekshirish uchun quyidagi HAVOLA tugmasini bosing.

QUVUR TEE QUVUR KEMAYTIRUVCHI QUVUR QOPQOG'I QUVUR BENDI SOZILGAN FITTINGLAR

Tirsakli payvandlangan quvur

Po'lat quvur tirsagi suyuqlik oqimi yo'nalishini o'zgartirish uchun quvur tizimidagi asosiy qismdir. U bir xil yoki turli nominal diametrlarga ega ikkita quvurni ulash va quvurni ma'lum bir yo'nalishda 45 gradus yoki 90 gradusga burish uchun ishlatiladi.

Sanoat quvurlari tirsagi uchun ulash uchi turi ANSI B16.25 ga muvofiq, dumbali payvandlashdir. Dumbali payvandlash dumbali payvandlash, dumbali payvandlash, qiyshiq uch bilan tavsiflanishi mumkin.

TIRSAK TURI

Tirsak yo'nalish burchagi, ulanish turlari, uzunlik va radius, material turlari bo'yicha o'zgarishi mumkin.

Yo'nalish burchagi bo'yicha tasniflanadi

Ma'lumki, quvurlarning suyuqlik yo'nalishiga ko'ra, tirsakni turli darajalarga bo'lish mumkin, masalan, 45 daraja tirsak, 90 daraja tirsak, 180 daraja tirsak, bu eng keng tarqalgan darajalardir. Shuningdek, ba'zi maxsus quvurlar uchun 60 daraja va 120 daraja mavjud.

45 graduslik payvandlash egilishi uchun 45 graduslik tirsak ham tasvirlangan.

Tirsak radiusi nima?

Tirsak radiusi o'rtacha egrilik radiusi. Agar radius quvur diametri bilan bir xil bo'lsa, u qisqa radiusli tirsak, shuningdek, SR tirsagi deb ataladi, odatda past bosimli va past tezlikli quvurlar uchun.

Agar radius quvur diametridan kattaroq bo'lsa, R ≥ 1,5 diametr, unda biz uni yuqori bosimli va yuqori oqim tezligidagi quvurlar uchun qo'llaniladigan uzun radiusli tirsak (LR tirsagi) deb ataymiz.

Agar radius 1,5D dan katta bo'lsa, har doim egilish deb nomlanadi. tirsak egilish quvur armaturalari. Masalan, 2d tirsak, 2d egilish, 3d tirsak, 3d egilish va boshqalar.

Materiallar bo'yicha tasniflash

Uglerodli po'lat, shuningdek, yumshoq po'lat yoki qora po'lat deb ham ataladi. Masalan, ASTM A234 WPB

Zanglamaydigan po'latdan yasalgan tirsaklarni qidiryapsizmi, batafsil ma'lumot olish uchun ushbu havolani bosing:ZANGLANMAYDIGAN PO'LAT TIRSAKLAR

Shakl turi

Teng tirsak yoki qisqartiruvchi tirsak bo'lishi mumkin

TIRSAK YUZASI

Qum portlashi

Issiq shakllantirishdan so'ng, biz sirtni toza va silliq qilish uchun qum puflashni tashkil qilamiz.

Qum portlashidan keyin, zanglamaslik uchun qora bo'yoq yoki zangga qarshi moy, issiq daldırma galvanizli (HDG), epoksi, 3PE, yo'qolgan sirt va boshqalarni ishlatish kerak. Bu mijozning iltimosiga bog'liq.

ISSIQLIK ISHLASH

1. Namuna xom ashyosini kuzatib borish uchun saqlang.

2. Issiqlik bilan ishlov berishni standartga muvofiq qat'iy ravishda tashkil qiling.

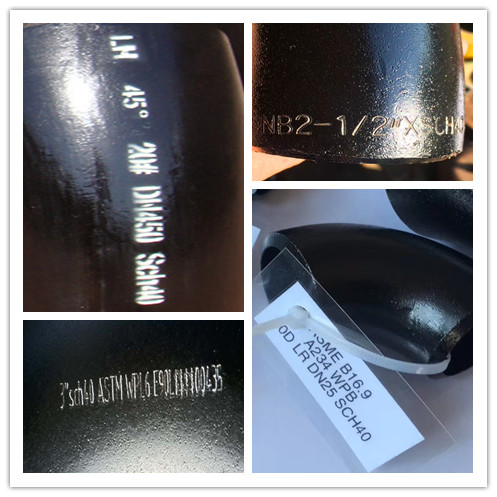

BELGILASH

Turli xil markalash ishlari, egri, bo'yash, yorliqlash mumkin. Yoki sizning iltimosingiz bo'yicha. Biz sizning LOGO'ngizni belgilashni qabul qilamiz.

TEKSHIRUV

1. O'lchov o'lchovlari, barchasi standart bardoshlik doirasida.

2. Qalinlik bardoshliligi: +/- 12,5% yoki sizning iltimosingiz bo'yicha

3. PMI

4. MT, UT, rentgen tekshiruvi

5. Uchinchi tomon tekshiruvini qabul qiling

6. MTC, EN10204 3.1/3.2 sertifikatini yetkazib berish

QADOQLASH VA YETKAZIB BERISH

1. ISPM15 ga muvofiq kontrplak korpusi yoki kontrplak pallet bilan qadoqlangan

2. Biz har bir paketga qadoqlash ro'yxatini qo'yamiz

3. Biz har bir paketga yuk tashish belgilarini qo'yamiz. Belgilash so'zlari sizning iltimosingiz bo'yicha.

4. Barcha yog'och qadoqlash materiallari fumigatsiyasiz

TSS

1. ANSI B16.9 uglerodli po'latdan yasalgan 45 darajali payvandlash tirsagi nima?

- ANSI B16.9 Karbonli po'latdan yasalgan 45 gradusli payvandlash tirsagi - bu quvurda yo'nalishni 45 gradusga o'zgartirish imkonini beruvchi quvur moslamasi. U suyuqlikning silliq oqishini ta'minlash va turbulentlikni kamaytirish uchun mo'ljallangan.

2. ANSI B16.9 uglerodli po'latdan yasalgan 45 gradusli tirsakli quvurni ishlab chiqarish uchun qanday materiallar ishlatiladi?

- ANSI B16.9 Karbonli Chelik 45 gradusli Tirsak chidamlilik va korroziyaga chidamlilikni ta'minlash uchun yuqori sifatli uglerodli po'lat materialdan tayyorlangan.

3. ANSI B16.9 uglerodli po'latdan yasalgan 45 graduslik tirsak trubkasidan foydalanishning afzalliklari nimada?

- Bu payvandlash tirsaklari ajoyib mustahkamlikka ega va yuqori bosimli muhitlarga bardosh bera oladi.

- Ular silliq o'tishni ta'minlaydi va quvurdagi stressni kamaytiradi, oqish yoki shikastlanishning oldini oladi.

- Ularni o'rnatish oson va samarali va muammosiz sanitariya-tesisat o'zgartirishlarini amalga oshirishga imkon beradi.

4. ANSI B16.9 uglerodli po'latdan yasalgan 45 gradusli payvandlash tirsaklari qanday tayyorlanadi?

- ANSI B16.9 uglerodli po'latdan yasalgan 45 gradusli payvandlangan egilishlar issiq egilish deb ataladigan jarayon yordamida ishlab chiqariladi, bu yerda uglerodli po'lat quvurni kerakli burchakka qizdirish va egish uchun maxsus uskunalar qo'llaniladi.

5. ANSI B16.9 uglerodli po'latdan yasalgan 45 gradusli payvandlangan tirsaklarning umumiy o'lchamlari qanday?

- ANSI B16.9 uglerod po'latdan yasalgan 45 gradusli payvandlash tirsaklari turli xil quvurlar talablarini qondirish uchun 1/2" dan 48" gacha bo'lgan turli o'lchamlarda mavjud.

6. ANSI B16.9 uglerodli po'latdan yasalgan 45 gradusli tirsak ham suyuq, ham gaz quvurlari uchun ishlatilishi mumkinmi?

- Ha, bu payvandlash tirsaklari suyuqlik va gaz quvurlari uchun mos keladi, chunki ular oqim yo'nalishini ishonchli va samarali o'zgartirishni ta'minlaydi.

7. ANSI B16.9 uglerod po'latidan yasalgan 45 graduslik egilish quvuri boshqa quvur armaturalari bilan mos keladimi?

- Ha, bu payvandlash tirsaklari mavjud quvur tizimlariga uzluksiz integratsiya qilish uchun boshqa ANSI B16.9 standart quvur armaturalari bilan mos keladigan tarzda ishlab chiqilgan.

8. ANSI B16.9 uglerodli po'latdan yasalgan 45 gradusli payvandlangan tirsak qaysi sanoat standartlariga mos keladi?

- ANSI B16.9 uglerodli po'latdan yasalgan 45 darajali payvandlash tirsagi Amerika Milliy Standartlar Instituti (ANSI) tomonidan uning sifati va ishonchliligini ta'minlash uchun belgilangan standartlarga javob beradi.

9. ANSI B16.9 uglerodli po'latdan yasalgan 45 darajali payvandlash tirsagini maxsus talablarga muvofiq sozlash mumkinmi?

- Ha, bu payvandlash tirsaklari turli xil burchaklar, o'lchamlar va material variantlari kabi muayyan loyiha talablariga mos ravishda sozlanishi mumkin, bu esa turli xil ilovalar uchun moslashtirilgan yechimni ta'minlaydi.

10. ANSI B16.9 uglerodli po'latdan yasalgan 45 gradusli tirsakli quvurni qayerdan sotib olsam bo'ladi?

- ANSI B16.9 uglerodli po'latdan yasalgan 45 darajali payvandlangan tirsaklar turli xil yetkazib beruvchilar va ishlab chiqaruvchilardan, onlayn va mahalliy dilerlar orqali mavjud. Yuqori sifatli mahsulotni ta'minlash uchun obro'li yetkazib beruvchini tadqiq qilish va tanlash tavsiya etiladi.

Issiqlik bilan ishlov berish

1. Namuna xom ashyosini kuzatib borish uchun saqlang.

2. Issiqlik bilan ishlov berishni standartga muvofiq qat'iy ravishda tashkil qiling.

Belgilash

Turli xil markalash ishlari, egri, bo'yash, yorliqlash mumkin. Yoki sizning iltimosingiz bo'yicha. Biz sizning LOGO'ngizni belgilashni qabul qilamiz.

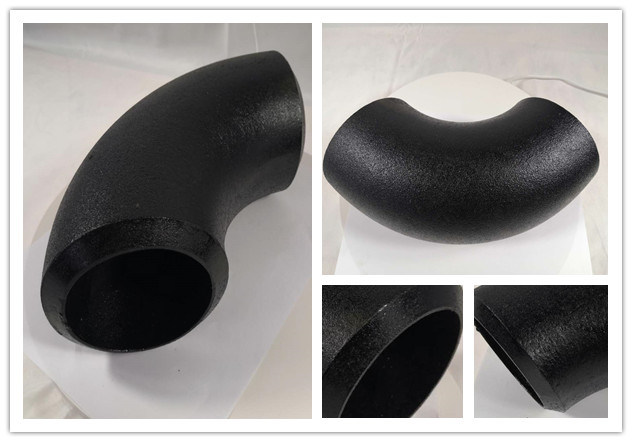

Batafsil fotosuratlar

1. ANSI B16.25 ga muvofiq qiya uchi.

2. Avval qum bilan ishlang, keyin mukammal bo'yash ishlari. Shuningdek, lak bilan qoplash mumkin.

3. Laminatsiya va yoriqlarsiz.

4. Hech qanday payvandlash ta'mirisiz.

Tekshirish

1. O'lchov o'lchovlari, barchasi standart bardoshlik doirasida.

2. Qalinlik bardoshliligi: +/- 12,5% yoki sizning iltimosingiz bo'yicha

3. PMI

4. MT, UT, rentgen tekshiruvi

5. Uchinchi tomon tekshiruvini qabul qiling

6. MTC, EN10204 3.1/3.2 sertifikatini yetkazib berish

Qadoqlash va yetkazib berish

1. ISPM15 ga muvofiq kontrplak korpusi yoki kontrplak pallet bilan qadoqlangan

2. Biz har bir paketga qadoqlash ro'yxatini qo'yamiz

3. Biz har bir paketga yuk tashish belgilarini qo'yamiz. Belgilash so'zlari sizning iltimosingiz bo'yicha.

4. Barcha yog'och qadoqlash materiallari fumigatsiyasiz

Quvur armaturalari quvur tizimidagi muhim komponentlar bo'lib, suyuqliklarni ulash, yo'naltirish, yo'naltirish, o'lchamlarni o'zgartirish, muhrlash yoki boshqarish uchun ishlatiladi. Ular qurilish, sanoat, energetika va kommunal xizmatlar kabi sohalarda keng qo'llaniladi.

Asosiy funktsiyalar:U quvurlarni ulash, oqim yo'nalishini o'zgartirish, oqimlarni ajratish va birlashtirish, quvur diametrlarini sozlash, quvurlarni muhrlash, boshqarish va tartibga solish kabi funktsiyalarni bajarishi mumkin.

Qo'llanilish doirasi:

- Binolarni suv bilan ta'minlash va drenajlash:Suv quvurlari tarmoqlari uchun PVX tirsaklar va PPR trislari ishlatiladi.

- Sanoat quvurlari:Kimyoviy muhitni tashish uchun zanglamaydigan po'latdan yasalgan flanjlar va qotishma po'latdan yasalgan tirsaklar ishlatiladi.

- Energiya tashish:Yuqori bosimli po'lat quvur armaturalari neft va gaz quvurlarida qo'llaniladi.

- HVAC (Isitish, shamollatish va konditsionerlash):Mis quvur armaturalari sovutgich quvurlarini ulash uchun, egiluvchan bo'g'inlar esa tebranishni kamaytirish uchun ishlatiladi.

- Qishloq xo'jaligi sug'orish:Tezkor ulagichlar purkagichli sug'orish tizimlarini yig'ish va demontaj qilishni osonlashtiradi.

-

Asme b16.9 jadvali 80 po'lat quvur armaturalari tee ...

-

zavod DN25 25A sch160 90 daraja tirsak quvur fi ...

-

Zanglamaydigan po'latdan yasalgan uzun bend1d 1.5d 3d 5d radiusli 3...

-

Lap bo'g'imi 321ss choksiz zanglamaydigan po'latdan yasalgan gardish ...

-

SUS 304 321 316 180 daraja zanglamaydigan po'lat quvur...

-

LStangless Steel 304L Butt-Weld Quvur Fitting Se...